As part of our ongoing “spotlight on members of the ESA” feature, we present two new members: Ceetak, a supplier of high-performance sealing solutions since 1974, and OVE Plasmatec GmbH, a family-owned company specializing in surface refinement of elastomers. Let’s give them the floor to tell their stories in their own words.

Ceetak: A Leading Global Provider of Sealing Solutions

Established in 1974, Ceetak supplies high performance sealing solutions to global customers across many industries focusing on automotive, oil & gas, life sciences & medical, defence, semiconductor, and renewable energy applications.

Our engineering team provide detailed seal design, material, and application engineering services to our customers. We maintain close technical links with a network of suppliers who are manufacturing experts in their field, including rubber moulding, diaphragm manufacture, PTFE machining and metal seal production. We also have established contacts at material producers and compounders, in addition to test houses and R&D establishments.

We coordinate supply from our manufacturing partners in America, Asia, and Europe, via one of our three warehouse facilities, either in Bedford (England), Aberdeen (Scotland) or Elst (Netherlands).

Our quality team provide support with aspects such as APQP, PPAP and annual revalidation, in addition to maintaining our quality approvals, auditing our suppliers and sample part audit inspection, working towards a zero-defect target on product supplied to our customers. In addition, they maintain our ISO 9001, 13485 and 14001 approvals and ensure our manufacturing partners retain relevant approvals including ISO/TS16949.

We have Environment, Social and Governance responsibilities at the core of all our activities. We recently achieved an EcoVadis Bronze sustainability rating at our first submission, and closely follow and engage with proposed regulations impacting our operations, including most recently the proposed PFAS EU restrictions and the EU Deforestation Regulation. We set high standards for ethics and fair business practices and insist that our suppliers do likewise and ensure compliance by way of regular audits of our preferred suppliers.

OVE Makes Seals More Powerful

Founded in 1990, OVE Plasmatec GmbH is a family-owned company and professional service provider dedicated to the surface refinement of elastomers. This includes cleaning, coating, treating, and servicing. The company is the sole provider of the low-pressure plasma process used for machine-based deep cleaning of seals.

A wide range of bonded coatings, together with years of experience and accumulated know-how, enables OVE to select the coating specifically for the application and function of the seal. Comprehensive services such as testing, custom packaging, and labelling help streamline the workflow for seal manufacturers and users. Quality inspections with coefficient of friction and torque measurements, as well as testing for PWIS and associated documentation, give customers the assurance they need. With around 30 employees and professional machinery, OVE processes an average of 80 million pieces per month.

Coatings can specifically change individual functions of the seals: for example, reduce friction coefficients and thus facilitate assembly, or increase the running performance in dynamic applications. They can reduce wear and thus increase service life. The latest coating can even make seals electrically conductive and dissipate unwanted electrostatic charge. When elastomer components are cleaned, treated, or even coated after the manufacturing process, it is proven that their performance increases significantly.

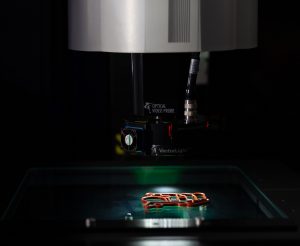

A new technology laboratory for plasma coating, coating development, and robotics:

OVE Plasmatec sets the course for the future of elastomer coating with the opening of its new technical lab at the company’s site in Weil im Schönbuch/Germany. The pioneers of high-performance coatings for elastomers and plastics want to play an active role in shaping the future of cleaning and coating technologies. The technical lab is equipped with state-of-the-art technology: a modern drying cabinet, a climate and salt spray chamber, resistance measuring devices, and a coating robot that applies improved or newly developed coatings on the surface of small batches. In the test and simulation facilities, the future of elastomer coating can be simulated, providing rapid feedback on new ideas. However, it is also about new coating processes. The technical lab also has a plasma coating chamber, developed for coating with inert gases as media, now opening up new possibilities.

According to the OVE experts, the first results of the new process are promising, and in times of an impending PFAS ban, it offers an alternative for new customer projects.